Base plates and anchor bolts are essential foundation components that provide stability and durability to light poles, high masts, and steel structures. Engineered for strength and corrosion resistance, they ensure safe installations across highways, industrial sites, and urban infrastructure projects.

Index

- What are Base Plates & Anchor Bolts?

- Importance in Light Poles & Structural Foundations

- Types of Base Plates

- Types of Anchor Bolts

- Material & Manufacturing Standards

- Technical Specifications & Sizes

- Base Plates vs Direct Burial Poles

- Applications in Infrastructure Projects

- Advantages of Using High-Quality Base Plates & Bolts

- Installation Process & Best Practices

- Quality & Testing Standards

- Buying Guide: How to Choose

- Price Factors & Cost Considerations

- Why Choose LightPole.co.in?

- FAQs

- Conclusion

What are Base Plates & Anchor Bolts?

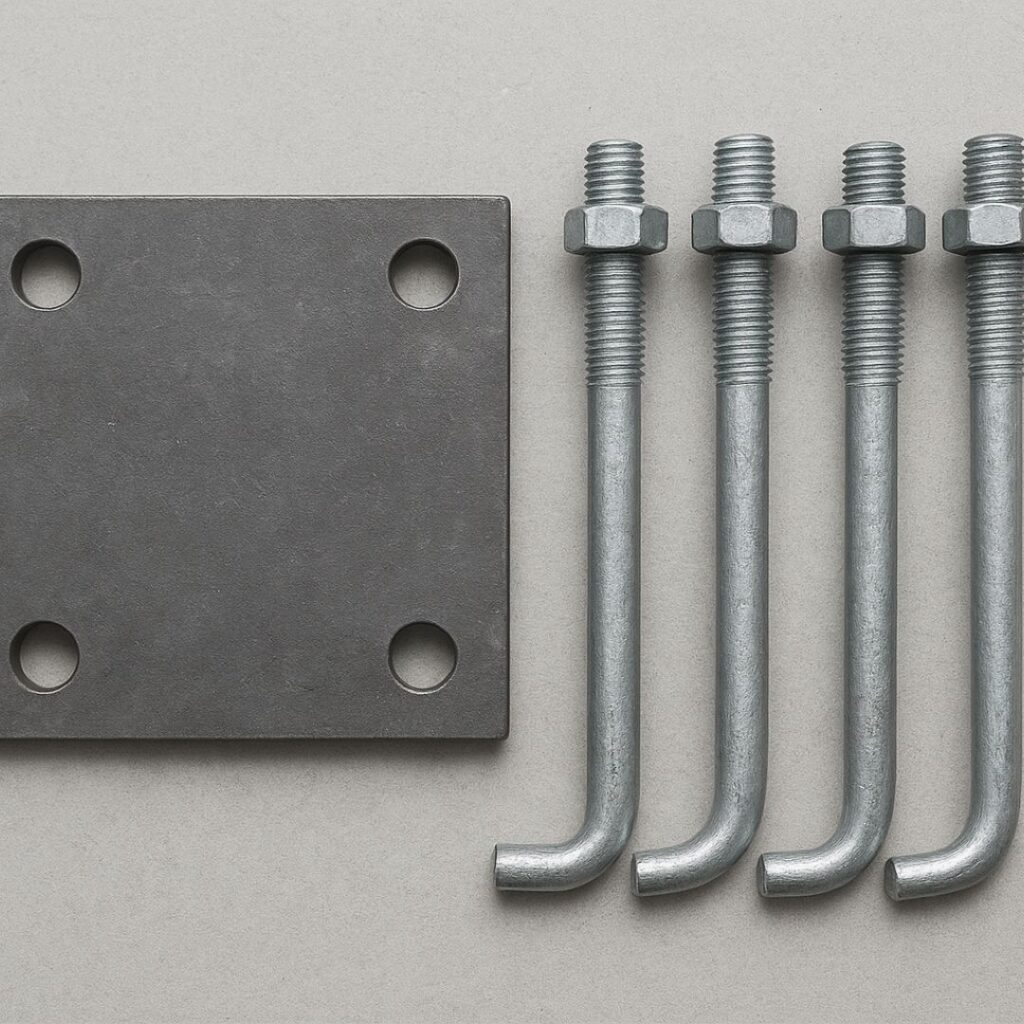

Base plates and anchor bolts are critical components in structural engineering and civil infrastructure. The base plate is a flat steel plate welded to the bottom of a pole or column, while anchor bolts secure that plate to the concrete foundation. Together, they transfer loads safely and prevent failures caused by external forces such as wind, vibration, and traffic impact.

Importance in Light Poles & Structural Foundations

In street lighting and high-mast installations, stability is non-negotiable. Base plates and anchor bolts ensure that poles remain upright, even in adverse conditions. Without them, poles risk premature leaning, cracking at the foundation, or catastrophic collapse.

- Provide load transfer between structure and foundation

- Allow easy pole replacement without disturbing concrete

- Improve service life with corrosion protection

Types of Base Plates & Anchor Bolts

Base plates vary depending on the application and pole design:

- Square Base Plates – Standard for most street light poles

- Round Base Plates – Used for aesthetic appeal in urban projects

- Customized Plates – Designed for telecom towers or heavy-duty applications

Types of Base Plates & Anchor Bolts

Anchor bolts come in multiple shapes and designs, each suited for different loads:

- L-shaped Bolts – Most common for light poles

- J-type Bolts – Provide additional grip in concrete

- U-bolts – Used for pipe and pole mounting

- Sleeve Anchor Bolts – Allow installation into existing concrete

- Expansion Bolts – Best for retrofitting applications

Material & Manufacturing Standards

Both base plates and anchor bolts are manufactured from high-strength steel. Common materials include:

- Mild Steel (MS)—Cost-effective and widely used

- Hot-Dip Galvanized Steel – Corrosion resistant, perfect for outdoor use

- Stainless Steel—Premium option for coastal regions with high humidity

All products are engineered as per IS, ASTM, and ISO standards, ensuring durability and reliability.

Technical Specifications & Sizes

At LightPole.co.in, we provide a wide range of options:

- Bolt diameters: M16 to M48

- Lengths: 300mm to 1200mm

- Base plate thickness: 12mm to 30mm

- Hole diameter: As per pole design

Base Plates vs Direct Burial Poles

| Feature | Base Plate Poles | Direct Burial Poles |

|---|---|---|

| Installation | Mounted with anchor bolts | Buried into ground |

| Durability | Higher, due to galvanization | Prone to soil corrosion |

| Maintenance | Easy replacement | Difficult & costly |

| Cost | Slightly higher upfront | Lower initial cost |

| Preferred For | Highways, industries, cities | Rural low-cost projects |

Applications in Infrastructure Projects

- Street Lighting Poles

- High Mast Lighting Towers

- Traffic Signal & Signage Structures

- Telecommunication Towers

- Industrial Sheds & Structural Columns

Advantages of Using High-Quality Base Plates & Anchor Bolts

- Superior corrosion resistance

- High tensile and yield strength

- Easy installation and maintenance

- Extended service life

Installation Process & Best Practices

Proper installation is key to long-term performance:

- Set anchor bolts in wet concrete using a template

- Allow sufficient curing time before pole installation

- Place base plate over bolts and tighten using torque wrench

- Check alignment and verticality of the pole

Tip: Always follow torque specifications and avoid overtightening, which may damage threads.

Quality & Testing Standards

Every batch of anchor bolts and base plates undergoes rigorous testing:

- Tensile & yield strength testing

- Coating thickness & galvanization tests

- Load transfer simulation under wind & vibration

Buying Guide: How to Choose the Right Anchor Bolts & Plates

When selecting, consider:

- Load Requirement – Height & weight of pole

- Environmental Factors – Coastal, industrial, or urban conditions

- Foundation Design – Size and depth of concrete pedestal

- Project Type – Highway, township, smart city, industrial plant

Price Factors & Cost Considerations

The cost of base plates & anchor bolts depends on:

- Material grade (MS, galvanized, SS)

- Bolt diameter & length

- Plate thickness & customization

- Order volume & delivery location

Why Choose LightPole.co.in?

LightPole.co.in is a trusted supplier of lighting poles, base plates, and anchor bolts across India. Here’s why clients choose us:

- High-strength, certified products

- Custom fabrication for any project

- Corrosion-resistant galvanization

- Pan-India delivery & installation support

FAQs

Q1: What is the function of base plates in light poles?

They provide a stable connection between the pole and foundation, ensuring load transfer and safety.

Q2: Which type of anchor bolt is best for highways?

L-shaped or J-type galvanized anchor bolts are recommended for highway poles due to high wind loads.

Q3: Are galvanized anchor bolts rust-proof?

Hot-dip galvanization provides strong corrosion resistance, though periodic inspection is advised.

Q4: How to calculate the right bolt size?

It depends on pole height, weight, and wind load. Our engineering team provides guidance for each project.

Q5: What is the average lifespan of anchor bolts?

With proper galvanization and maintenance, they last 20–30 years.

Conclusion

Strong foundations are the key to long-lasting infrastructure. Base plates and anchor bolts are the unsung heroes that ensure the safety, stability, and durability of light poles, masts, and steel structures. Choosing the right supplier makes all the difference.