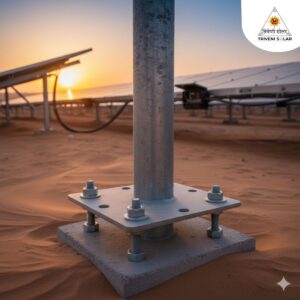

Base plate mounted poles are durable steel poles designed for safe and reliable mounting in streets, highways, and industrial areas. They provide easy installation, corrosion resistance, and long-lasting performance, making them ideal for urban and industrial lighting applications.

Table of Contents

- Introduction to Base Plate Mounted Poles

- Benefits of Base Plate Mounted Poles

- Types & Materials

- Technical Specifications & Dimensions

- Installation & Maintenance Tips

- Applications in Urban and Industrial Areas

- Comparison Table of Base Plate Poles

- FAQs about Base Plate Mounted Poles

- Conclusion & Call to Action

Introduction to Base Plate Mounted Poles

Base plate mounted poles are essential components for modern street and industrial lighting. Unlike embedded poles, these poles are securely bolted to a concrete foundation, offering stability, durability, and flexibility in installation. Whether for highways, urban streets, parks, or industrial zones, base plate mounted poles provide a reliable solution for long-term outdoor lighting.

What are Base Plate Mounted Poles?

These poles feature a flat steel base plate with anchor bolts, allowing for precise alignment and strong attachment to a concrete foundation. The design ensures superior resistance to wind loads, vibrations, and environmental stress.

Why They Are Important for Lighting Systems

Base plate mounted poles ensure minimal maintenance, high safety standards, and a professional aesthetic for any outdoor space. They are ideal for areas where pole placement might require future adjustments or relocations.

Benefits of Base Plate Mounted Poles

- Durability & Corrosion Resistance: Manufactured using hot-dip galvanized steel or powder-coated finishes, these poles withstand harsh weather and environmental conditions.

- Easy Installation & Maintenance: Base plate mounting simplifies installation and replacement, saving both time and labor costs.

- Cost-Effectiveness & Safety: Strong anchor bolts reduce structural risks, ensuring safety while providing long-term value.

- Customizable Options: Poles can be tailored for height, load capacity, and finish according to project requirements.

Types & Materials

Hot-Dip Galvanized Steel Poles

These poles are coated with a protective zinc layer to prevent rusting and corrosion. Ideal for coastal and industrial regions.

Aluminum Poles

Lightweight yet strong, aluminum poles are corrosion-resistant and easy to transport and install.

Powder-Coated Poles

Offering aesthetic appeal and additional weather protection, powder-coated poles are suitable for urban and residential lighting.

Technical Specifications & Dimensions

| Specification | Details |

|---|---|

| Height | 3m–12m (Customizable) |

| Diameter | 60 mm – 219mm |

| Material | Hot-Dip Galvanized Steel / Aluminum / Powder-Coated Steel |

| Wind Resistance | Up to 150 km/h |

| Load Capacity | Designed per IS 875 & IRC standards |

| Anchor Bolts | M16–M24, Stainless Steel |

Base Plate Mounted Poles Installation & Maintenance Tips

How to Mount Base Plate Poles

1. Prepare a concrete foundation according to pole height and weight.

2. Align anchor bolts accurately using the base plate.

3. Secure bolts and tighten to manufacturer specifications.

4. Check vertical alignment using a spirit level.

Common Mistakes to Avoid

- Incorrect foundation size leading to instability.

- Using substandard bolts causes premature wear.

- Poor alignment affecting aesthetics and safety.

Long-Term Care

Regular inspection for rust, loose bolts, and paint damage ensures the pole’s longevity. Touch-up painting and bolt tightening are recommended every 2–3 years.

Applications in Urban and Industrial Areas

- Street & Highway Lighting: Ensures uniform illumination and safety on roads.

- Parks & Public Spaces: Adds aesthetic appeal while providing functional lighting.

- Industrial & Commercial Zones: Durable poles for high-stress environments, including factories and warehouses.

Comparison Table of Base Plate Mounted Poles

| Material | Height Range | Load Capacity | Corrosion Resistance | Cost |

|---|---|---|---|---|

| Hot-Dip Galvanized Steel | 3m – 12m | High | Excellent | Moderate |

| Aluminum | 3m – 10m | Medium | Very Good | High |

| Powder-Coated Steel | 3m – 12m | High | Good | Moderate |

FAQs about Base Plate Mounted Poles

How long do base plate poles last?

With proper installation and maintenance, base plate-mounted poles can last 15–25 years depending on material and environmental conditions.

Are they suitable for coastal areas?

Yes, hot-dip galvanized and powder-coated poles offer excellent corrosion resistance for coastal and high-humidity regions.

Can they be customized?

Absolutely. Poles can be customized for height, diameter, material, and finish to suit specific project requirements.

Conclusion & Call to Action

Base plate mounted poles from LightPole.co.in provide a perfect combination of durability, safety, and ease of installation for all urban and industrial lighting needs. With a range of materials, customizable options, and long-lasting performance, these poles are ideal for highways, parks, streets, and industrial zones.

Order your base plate mounted poles today and experience the unmatched quality and reliability that LightPole brings to outdoor lighting projects. Contact us now to get a personalized quote!